CFRP Milling Cutter

For the Machining of Composite Materials and Delamination-free milling of unidirectional CFRP

The machining of modern materials such as carbon fibre reinforced plastics (CFRP) is a growing challenge for tooling manufacturers. In order to economically machine the latest generation of this high-tech material, effective high-tech tools are required. Guhring's CFRP milling cutters prevent the delamination or fibre projections on the component as well as any thermal damage whilst operating with extreme efficiency.

With the new CFRP varieties there is a noticeable trend towards reduced resin content and above all the unidirectional orientation of the fibres. Whilst the fibres in woven condition are firmly embedded in the resin fibre matrix, in the unidirectional CFRP they lie next to each other in the resin. The result shows a lack of interlocking embedding.

This development considerably affects the reliability of the machining process for these materials as, for example, milling can cause the fibres to easily tear out of the composite. The higher the cutting forces, the greater the effect.

Typical delamination of a milled unidirectional CFRP workpiece edge and unidirectional CFRP workpiece edge when milled with Guhring's new CFRP milling cutter.

Intelligent solutions form Guhring

Guhring's research centre for composite materials developed a new milling cutter with an innovative cutting edge arrangement. Two cutting edges are positioned to each other at a helix angle of 25º, in addition it possesses unequal spacing of the cutting edges at the circumference of a practice perfected with carbide milling cutters and reamers.

The advantages of this new geometry are:

- no tendency to premature delamination

- extremely smooth operation, even with unstable clamping

- delamination-free machining

- longer tool life

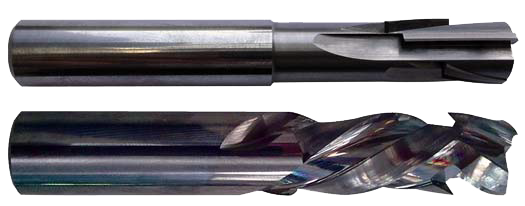

Milling cutter with PCD cutting edges and new Guhring cutting edge geometry and milling cutter with diamond coating and new Guhring cutting edge geometry.